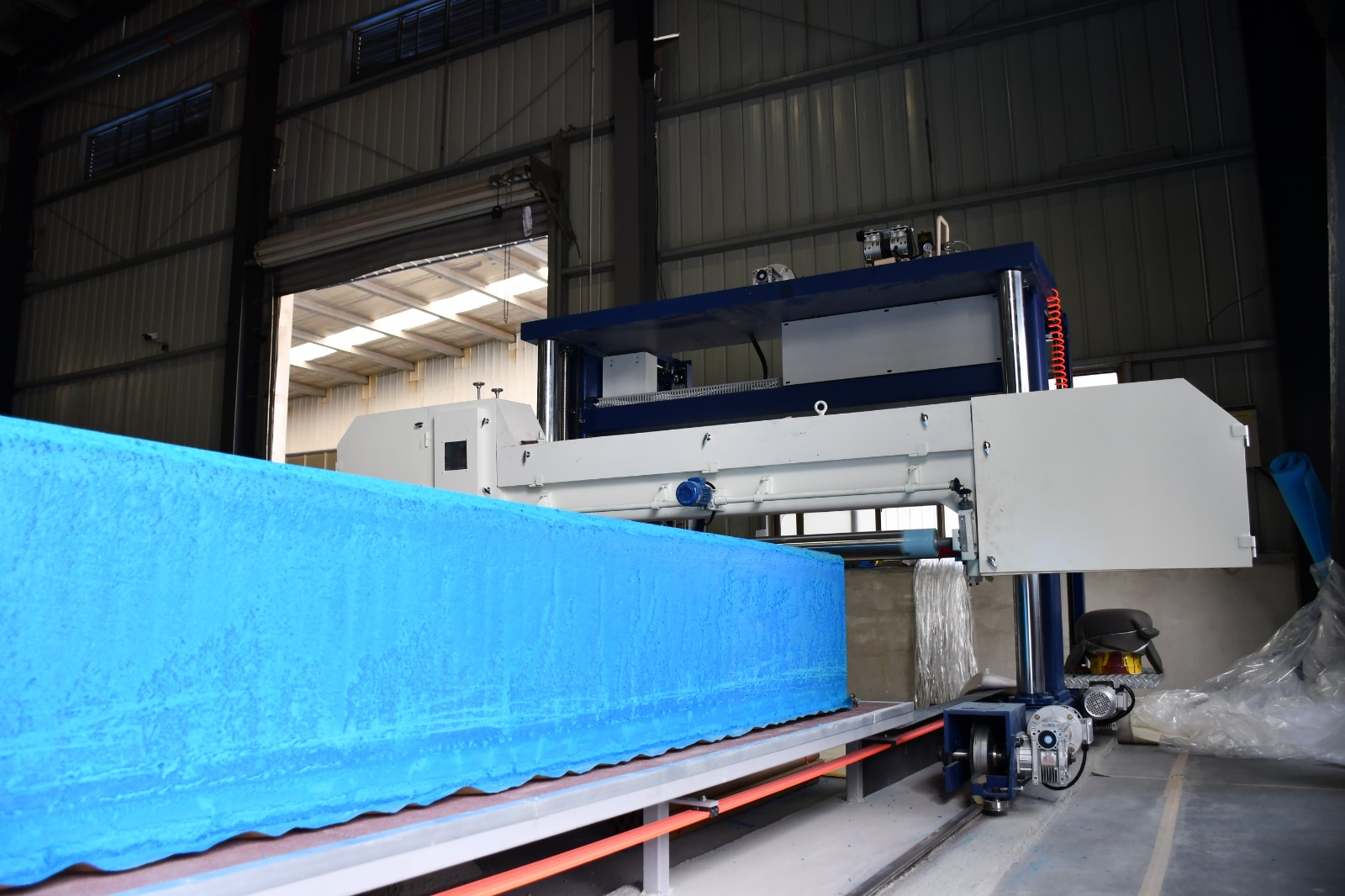

long peeling horizontal foam block cutting machine

2023-05-04 15:44

In the field of industrial manufacturing, the latest advances in foam cutting technology have arrived. Long peel foam block cutting machines are revolutionizing the way foam products are manufactured, reducing production time and increasing efficiency.

These machines are designed to cut foam blocks into thin strips while minimizing waste and increasing precision. The cutting process involves a harp-like system that cuts through blocks of foam to produce smooth, uniform foam strips that can be used in a variety of applications.

One company using this technology is Foam Supplies Inc., a leading foam supplier based in St. Louis, Missouri. The company recently installed a new long strip foam block cutting machine, greatly increasing their production capacity.

“We are very excited about this new machine,” said John Televantos, Vice President of Sales and Marketing for Foam Supplies Inc. “It allows us to produce more foam in less time, which is great for our customers. A huge benefit."

As the demand for foam products continues to grow, the need for faster, more efficient production methods becomes increasingly important. Long peel foam block cutters offer a solution to this problem, capable of producing thousands of foam strips in a single day.

The machines are also capable of cutting foam blocks of various sizes and densities, making them ideal for a wide range of applications from packaging materials to insulation and cushioning products.

In addition to their efficiency and versatility, long stripping foam block cutters are also environmentally friendly because they generate less waste than traditional cutting methods. This makes them a popular choice for companies looking to reduce their environmental footprint while still maintaining high levels of productivity.

Overall, the introduction of the Long Strip Foam Block Cutting Machine is a significant development in the field of industrial manufacturing. As more companies adopt this technology, we can expect to see faster production times, higher efficiencies and more sustainable manufacturing processes in the foam industry.

Get the latest price? We'll respond as soon as possible(within 12 hours)