Streamlining Your Cutting Process With A CNC Contour Foam Block Cutting Machine

2023-06-14 11:26

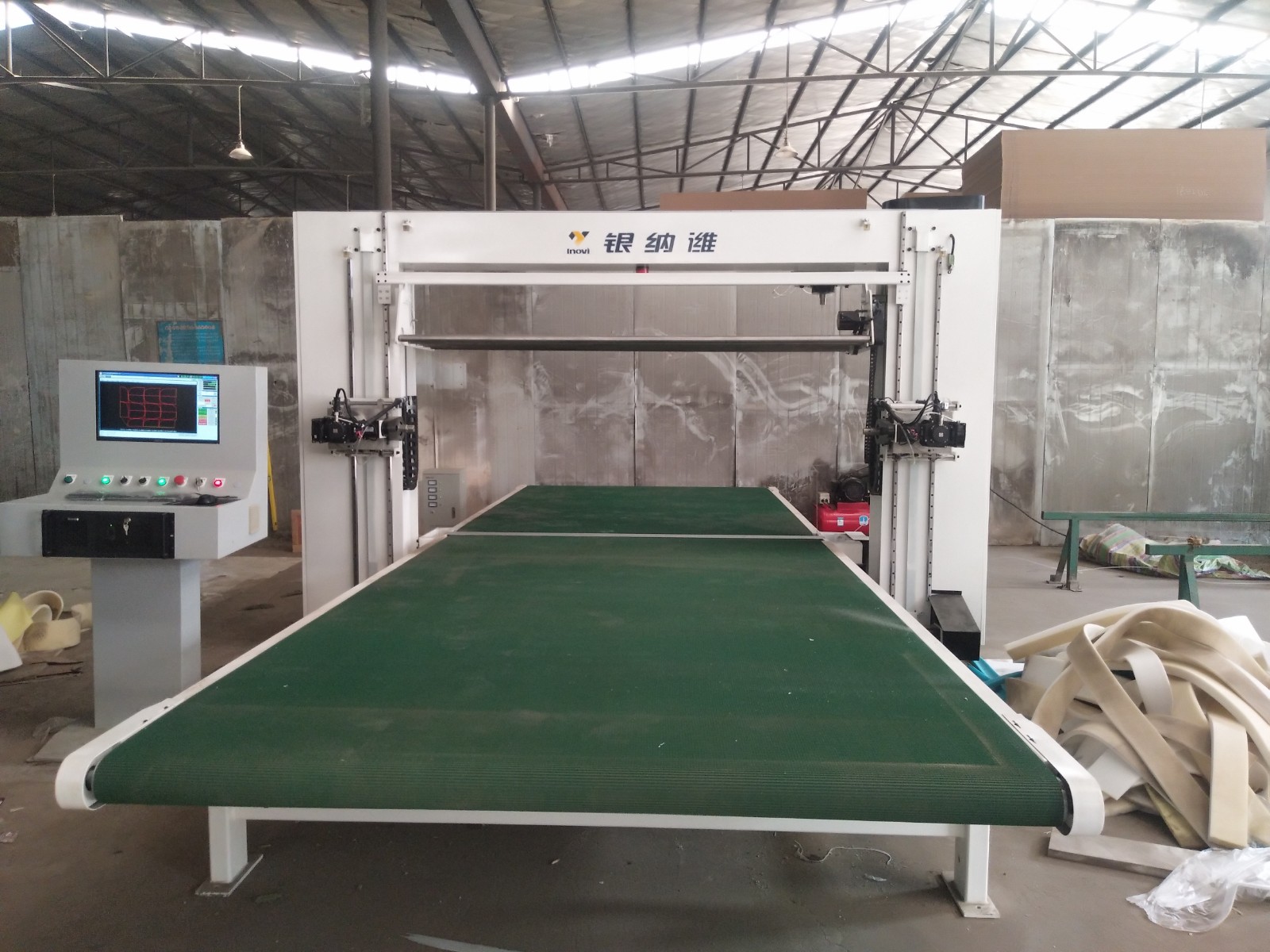

Streamlining Your Cutting Process With A CNC Contour Foam Block Cutting Machine

Cutting foam blocks can be a tough, time-consuming task that demands precision and accuracy. However, with the increasing demand for foam block cutting in different industries, manufacturers have come up with modern CNC contour foam block cutting machines that simplify the cutting process.

A CNC (Computer Numerical Control) foam block cutting machine is an automated cutting device that uses a computer-aided design (CAD) file to guide its cutting blades to create precise foam shapes and sizes. These machines are available in numerous types and sizes, making them suitable for a variety of cutting purposes.

Here are some reasons why a CNC contour foam block cutting machine is your best bet:

1. Precision and Accuracy - One of the most significant advantages of using a CNC foam block cutting machine is the precision and accuracy it offers. Irrespective of the design complexity or intricacy, it produces smooth, consistent, and highly-accurate cuts that exceed human capabilities.

2. Time-Saving - By automating the cutting process, a CNC foam block cutting machine significantly reduces production time. Unlike manually-operated cutting tools that require time-consuming setup and frequent operator intervention, CNC machines run continuously until the programmed cuts are completed, thereby, saving valuable time and reducing production costs.

3. Versatility - CNC foam block cutting machines employ a variety of cutting tools and blades, enabling them to cut different foam materials such as open-cell, closed-cell, and rigid foam. They can also create intricate forms like letters, logos, and shapes, providing limitless creative possibilities.

4. Consistency - With CNC foam block cutting machines, every cut is precisely the same as the previous ones. This consistency is particularly vital when creating identical shapes for a repetitive foam cutting project.

5. Safety - Unlike manual foam cutting tools that require human intervention, CNC machines operate automatically, minimizing the risk of operator harm, making foam block cutting a safer process.

In conclusion, the CNC contour foam block cutting machine is an invaluable asset for businesses that require a quick, consistent, and precise cutting process. They provide a perfect combination of speed, accuracy, and versatility while eliminating potential human errors. Despite the little extra cost required to acquire these machines, they are a necessity for modern businesses that wish to remain competitive and provide efficient services.

Get the latest price? We'll respond as soon as possible(within 12 hours)